At Parkway, we provide a leading range of industrial water treatment related products, services & solutions. We take the time to understand your specific water and/or wastewater treatment related requirements and work collaboratively through the process development, project engineering and ultimately project execution phase, including fabrication, installation and commissioning, to ensure project success.

|

SUCCESSFUL WATER TREATMENT SOLUTIONS ACROSS THE PROJECT LIFECYCLE

|

||

|

SYSTEMATIC WATER TREATMENT PROCESS

Parkway is an established industrial water treatment company with turnkey (engineering, procurement & construction, EPC) project delivery capabilities. We work closely with our clients to provide a range of industry leading integrated water treatment solutions. In order to ensure your next water and/or wastewater treatment project is a success, we have prepared a short 10-Step Guide outlining important steps in the process, starting with water sampling and analysis, through to an operational plant that is reliably meeting all your treatment objectives. Our helpful guide (see below) outlines important considerations for ensuring the effective design, fabrication and installation of a successful water or wastewater treatment project and also outlines how Parkway can support you on your journey.

1) WATER SAMPLING AND ANALYSIS

The water and wastewater treatment journey starts with sampling and analysis of your raw water or influent, respectively, to determine the key physical, chemical and biological characteristics. Representative sampling, as well as accurate testing and analysis of a broad range of relevant parameters, is an important foundation for understanding the properties of your water and/or wastewater source and determining what might be achievable. At Parkway, we provide a range of analytical testing services, including:

In addition to our inhouse testing facilities and our partner facilities at Victoria University, we work closely with a range of NATA accredited laboratories to provide timely and accurate testing services, for a wide range of commercial and industrial applications. Further details about these services are outlined in the analytical testing services section of our website. If you are unsure about what type of sampling and/or testing may be suitable for your specific treatment objectives, please Get in Touch (refer tab). Our team of experienced technicians and water treatment specialists at Parkway, can assist in determining the most suitable testing requirements.

2) DETERMINE TREATMENT OBJECTIVES

Whilst performing comprehensive water sampling and analysis is important, ultimately, the sufficiency of this testing, can only be determined in the context of what the overall treatment objectives are. The objectives for water treatment and wastewater treatment are contrasted by the desire for water to be treated to make it safe for the purpose of human consumption, as opposed wastewater being treated for the purposes of making it safe to be released (discharge) into the natural environment. It is important to accurately determine treatment objectives from the outset, in order to focus the evaluation of suitable treatment processes and ensure their efficacy against the respective objectives. Common water treatment objectives include treating surface or groundwater including bore water, to ensure the treated water meets Australian Drinking Water Guidelines, as outlined by Water Quality Australia, an Australian Government Initiative. Similarly, the process for effectively managing wastewater from its source, through its collection, transfer, and treatment, to its disposal or reuse, in Australia, is outlined in the Australian Wastewater Quality Management Guidelines, published by Water Services Association of Australia. Depending on the treatment objectives, the proposed treatment process is likely to need to comply with a range of standards and regulations, which should be considered from the outset, to ensure an efficient design process to ensure the proposed solution is fit-for-purpose.

3) DESIGN SUITABLE TREATMENT PROCESS

Once the treatment objectives have been outlined (Step 2) and the characteristics of the raw water or wastewater have been determined (Step 1), a suitable treatment process needs to be systematically developed. At Parkway Process Solutions, we specialise in the development of robust and effective treatment processes incorporating a range of conventional water treatment processes including:

Process Screening Given the typical complexity of raw water, an effective treatment process will generally require sequential treatment through a series of unit operations (process steps), as outlined above. Parkway has developed a methodical approach to systematically evaluating a range of unit operations to ensure the respective treatment objectives are achieved in an efficient manner. This process involves:

Flowsheet Development Based on the successful performance of the respective unit operations, these will be integrated in a logical sequence, to initial develop a block flow diagram (BFD), followed by the development of an integrated flowsheet, which is often depicted in the form of a process flow diagram (PFD). Process Equipment Selection Once the PFD has been developed, our process engineering team develop detailed equipment lists, based on overall treatment objectives and broader project requirements. At Parkway, we work closely with many global brands including DuPont, Graco, Grundfos, Hach, Georg Fischer, Mann+Hummel, Prominent, Purolite, Tsurumi, amongst many others, as well as leading local suppliers, including Aquacorp, Envirofluid, Fluidpro, Polymaster, Total Rubber, UV Guard, Waterco and 100’s of other leading industrial water treatment related suppliers. As the master distributor for these brands in Australia, we provide efficient procurement options as we carry stock across our Australian store network, and also provide technical support for our clients, to ensure project success. Process Evaluation Before transitioning to the project execution phase, depending on the scale of the project, it may be appropriate to perform technoeconomic evaluation/s, to ensure the proposed treatment process is not only fit-for-purpose, but also represents suitable value for money. Additional information about these services, including feasibility studies performed by Parkway, are outlined in the Process Development Services section. Process Design Package Depending on the scale of the project, project delivery model and the scope of supply, Parkway be required to provide a suitable process design package, which provides a range of process engineering related deliverables, required for the successful delivery of the process plant, within the broader project context. Process Technology Package For more advanced projects, requiring more innovative process flowsheets incorporating proprietary process technologies developed by Parkway, Parkway will provide a process technology package as part of the process engineering related deliverables.

4) DEVELOP FIT-FOR-PURPOSE PROJECT DESIGN

Following development of a Suitable Treatment Process (Step 3) which is represented by the process plant, the remainder of the project will need to be developed collaboratively with the client, to ensure the project remains in line with the project objectives. Additional requirements, typically required to support the treatment process (process plant) include:

Whilst Parkway specialises in the development, design and delivery of the core treatment process, Parkway has additional capabilities in relation to BOP, and works closely with strategic partners to be able to support successful project delivery. Parkway often works closely with civil engineering and construction contractors, to ensure the process plant can be effectively integrated into broader project and site-specific related requirements.

5) DETERMINE APPROPRIATE PROJECT EXECUTION STRATEGY

Depending on a specific project location, type and scale, Parkway will endeavour to provide the most effective and best value solution to support our clients meet their project objectives and achieve success. In the simplest scope of supply, Parkway supplies a range of industrial water treatment related products and services, on a “supply only” basis. Where Parkway has been engaged during the earlier project phases, particularly during the process development phase, Parkway will work closely with the client to develop a project execution plan (PEP), which may involve Parkway offering to deliver a given project through the following commercial models:

Alternatively, Parkway may elect to provide a more limited scope focused on:

Additional details related to project development services provided by Parkway are outlined in the Project Engineering Services section of the Parkway website.

6) WORKSHOP FABRICATION

Once the PEP has been developed, and the project has transitioned to the execution phase, before site works commence, fabrication related activities typically commence in a workshop to:

In addition to an established workshop at PPS-Darwin, the primary fabrication workshop operated by Parkway is in the South East of Melbourne in Victoria, through a wholly-owned subsidiary, Tankweld. Tankweld provides a wide range of industrial fabrication services including specialist aluminium, stainless steel and carbon steel rolling, bending and fabrication services, as outlined below. Fully Equipped Workshop

Key Equipment

Fabrication

Additional details about Parkway’s workshop fabrication capabilities, is outlined in the Tankweld section.

7) ONSITE INSTALLATION

Whilst Parkway specialises in the development, design and delivery of the core treatment process, Parkway has additional capabilities in relation to the balance of plant (BOP), and works closely with strategic partners to be able to support successful project delivery, including onsite installation. In order to maximise the efficiency of onsite installation, during the workshop fabrication process (Step 6), Parkway perform a range of important functions in the workshop, including:

Parkway often works closely with a range of specialised contractors (including electrical and civil), to ensure the process plant can be effectively integrated into broader project and meet site-specific related requirements. Additional details about Parkway’s onsite installation related capabilities, is outlined in the following sections:

8) START-UP & COMMISSIONING

Where Parkway has provided onsite installation (Step 7) related activities, Parkway will typically provide the corresponding start-up and commissioning related support services, which directly relate to the relevant scope. The important process development activities performed earlier in the project lifecycle (Steps 3 & 4), provide the Parkway process specialists with a strong technical basis, to ensure the process plant is successfully commissioned, with key performance parameters in line with the engineered design. Additional details about Parkway’s start-up and commissioning related capabilities, is outlined in the following sections:

9) OPERATE & MAINTAIN

Following successful commissioning (Step 8), the water or wastewater treatment plant is officially handed over to the client to operate and maintain the plant. During regular operations of the treatment plant, a range of consumables including water treatment chemicals, filters, membranes and other consumables are often required by the operator. As an established Australian distributor of these products from leading global brands, Parkway ensures our clients have reliable access to everything they need to maintain reliable operations. In addition to regular operations, treatment plants typically require scheduled maintenance to ensure effective performance. As outlined above, Parkway provide a range of products and services, including experienced operators and technicians, to maintain reliable operations and troubleshoot any issues. Additional details about Parkway’s operate and maintain related capabilities, is outlined in the following sections:

10) UPGRADE & RETROFIT

As treatment plants age, particularly as they reach their design life, it can be challenging to ensure reliable performance, particularly if project or regulatory requirements have become more stringent since the plant was first installed. In order to ensure water treatment related infrastructure remains safe, effective and fit-for-purpose, it may be appropriate to perform periodic reviews. As experienced process engineers, Parkway is well placed to assess project performance against a range of parameters, and where relevant, make recommendations which may involve a treatment plant upgrade or retrofit, depending on the specific requirements. In many respects, the upgrade of an existing treatment plant (brownfield project) has many similarities to a new (greenfield) project, as the raw of wastewater needs to be sampled and analysed (Step 1), new objectives determined (Step 2) . . . all the way through to the successful design, installation and commissioning of the upgrades. Additional details about Parkway’s local capabilities, is outlined in the following sections:

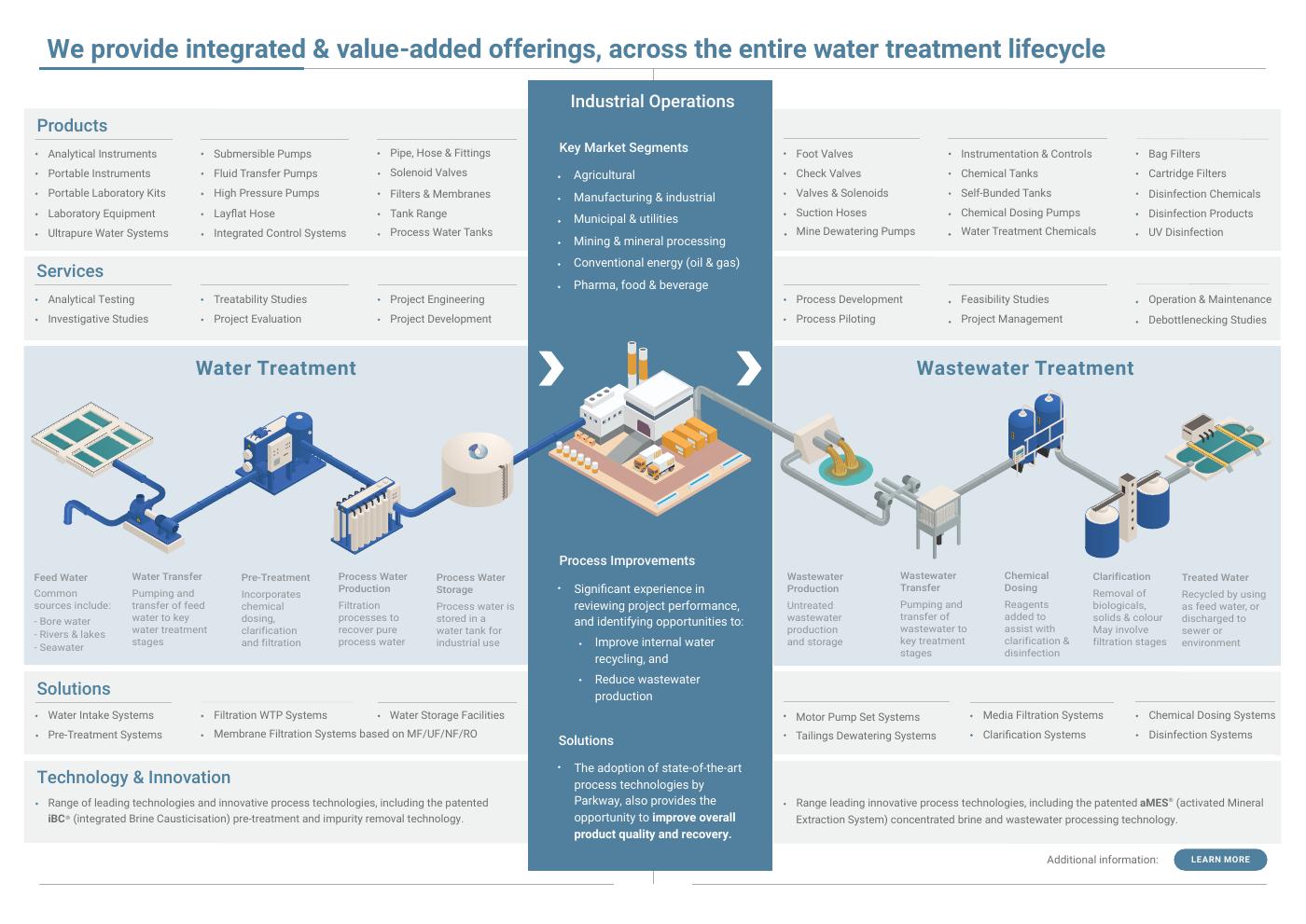

WATER TREATMENT OFFERING

Parkway Process Solutions is a leading provider of industrial and innovative water treatment related, products, services, solutions & technology across Australia, with global reach through our strategic partners. Additional information about Parkway, including the value-added solutions we provide across the entire water treatment lifecycle, is outlined in the Parkway Process Solutions – Corporate Profile brochure, presented below.

GET IN TOUCH

Parkway provide a range of leading products and services as part of our commitment to providing safe, reliable and cost-effective industrial water and wastewater treatment solutions, across Australia. For further information about how Parkway may be able to assist with your industrial water and/or wastewater treatment related requirements, reach out to our friendly team with relevant details regarding your project. Please ensure your enquiry provides an overview of your project and relevant technical information. All enquiries, including relevant technical information, should be sent to solutions@pwnps.com. Your enquiry will be promptly reviewed by our relevant technical teams, who will be in touch promptly, with any questions and/or feedback, on how we may be able to assist you with your specific requirements. Depending on your project specific requirements, we may be able to assist from our either our head office in Melbourne, or through one of our Parkway Process Solutions (PPS) branches. Further details regarding our PPS Branch locations is outlined here. |

|||