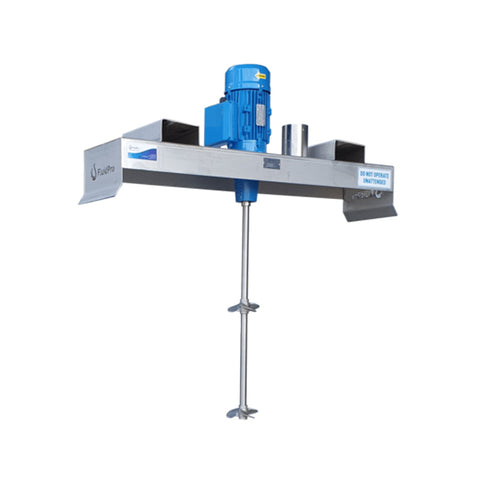

Fluidpro DM10 Series IBC Mixer, 180rpm, 450mm x2 Folding SS316 Blades, for Solids in Suspension

Fluidpro DM10 Series IBC Mixer, 180rpm, 450mm x2 Folding SS316 Blades, for Solids in Suspension

Optimise processing times and operations with the Fluidpro range of IBC mixers. Designed to efficiently blend liquid products and solids in suspension, the stainless steel IBC mixers are portable, robust and can drastically improve your processing efficiency.

Vendor: Fluidpro

Unavailable

KEY FEATURES

- Portable, durable and robust IBC mixer

- All wetted parts are manufactured from 316 stainless steel

- Fully enclosed IP56 electric motor

Optimise your processing times and operations with the Fluidpro range of IBC mixers. Designed to efficiently blend liquid products, semi-solids and solids in suspension, the Fluidpro specialised IBC mixers and agitators are portable, robust and can drastically improve your processing efficiency.

Intermediate Bulk Containers (IBCs), also known as plastic tote tanks, have revolutionised the way liquids are stored and transported, allowing fluids to be mixed inside the container to reduce process stages and streamline your production. Fluidpro IBC mixers feature a stainless steel welded bridge to fit snugly to your IBC tanks, creating a portable all-in-one mixing system.

With a heavy-duty nosecone assembly, incorporating shaft support bearing and integrated quick release shaft coupling, the innovative fluidpro IBC mixer designs will quickly improve your business productivity and minimise downtime.

Parkway also stock a wide range of IBC tanks, mixers & bunding, specialty Camlock & related fittings, layflat hoses, valves and everything else you need to create an IBC based system to meet your project specific requirements.

ADDITIONAL FEATURES

- Portable design for easy transport

- All wetted parts are 316 stainless steel.

- AF30 blades specially designed for use in IBC’s

- Fully welded Heavy duty stainless steel mounting bridge for snug fit to IBC tanks

- Forkliftable Frames

- Cast Aluminium Mixer pedestal with shaft support bearing

- Range of innovative fold-out impeller design for mixing different viscosity fluids (see photo gallery, available separately).

- Quick release shaft coupling

- IP56 electric motor, fully enclosed

APPLICATIONS

- A wide range of industrial, chemical storage and water treatment related applications, including:

- Liquid blending

- Chemical mixing

- Cosmetics manufacturing

- Water treatment

- Wastewater pH correction

- Liquid fertiliser blending

- Food and beverage processing

- Wine processing

- Product resuspension

- Vessel cleaning

PRODUCT PACKAGE INCLUDES

- DM10 Series IBC Mixer, 180rpm, 450mm x2 SS316 folding Fluidfoil blades, for solids in suspension.

- Please note, the IBC Mixer is supplied as a packaged unit, and excludes the IBC tanks, which are available separately.

SPECIFICATIONS

| Brand | Fluidpro |

| Model | FLU-DM-10.S25.GDTT150-SS-FIXED-RPM180 |

| Gross Dimensions | |

| Weight | - kg, approximately |

| Length | - mm |

| Width | - mm |

| Height | - mm |

| Application | General blending where there are some solids in suspension (<3000Cp) |

| Propellor Type | 2 x 450 mm diameter Fluidfoil folding (x2 blades) |

| Material of Construction | 316 stainless steel |

| Shaft Diameter | 25.4 mm 316SS |

| Shaft Length | 800mm 316SS |

| Shaft Connection | Quick release type |

| Seal Type | Lip seal |

| Mounting | 316 Stainless steel bridge type - heavy duty pedestal |

| Mount Position | Centre vertical |

| Agitation Speed | 180rpm - fixed speed (excludes VSD) |

| Power Req | 1.5 kW, 3-phase, 415V, 50Hz |

| Motor Type | IP56 electric motor, fully enclosed |

The contents of this document are provided as a guide only and are subject to change without prior notice, and without any subsequent liability to Parkway Process Solutions Pty Ltd (the “Company”) or any of its related entities. The actual shape, colour, size, performance and/or any other parameters of the item/s and/or product/s and/or system/s supplied by the Company, may vary materially from those outlined by the Company.

All brand names and product names outlined in this document are either trademarks or registered trademarks and belong to the respective companies.

ALL INFORMATION OUTLINED HEREIN IS PROVIDED AS A GUIDE ONLY AND SHOULD NOT BE RELIED UPON FOR ANY PURPOSE, WITHOUT CONFIRMING SUCH DETAILS WITH THE COMPANY BEFORE MAKING A PURCHASE AND/OR UTILISING A GIVEN PRODUCT.

ADDITIONAL RESOURCES

PRODUCT INFORMATION SHEET (PIS)

Detailed information about the DM10 Series IBC Mixer is outlined in the product information sheet.

DOWNLOAD

USER MANUAL

Detailed information including instructions on how to operate the DM10 Series IBC Mixer is outlined in the attached user manual.

DOWNLOAD